Economically, there is a balance between the cost of ordering a spare part and the cost of repairing a faulty part. When the cost of repair becomes a significant percentage of the replacement cost, it becomes economically feasible to have a spare part made. Unrepairable parts are considered consumables and are typically scrapped when they are determined to be faulty.

What is a Spare Part?

A spare part, also known as a service part, is a pre-manufactured interchangeable component held in inventory and used for the repair or replacement of faulty units. Spare parts are an important aspect of logistics engineering and supply chain management, and they often consist of specialized spare parts management systems. Spare parts are a result of interchangeable parts and the industrial development of mass production.

In terms of maintaining business continuity and quality, it is crucial to have either pre-prepared parts or business partners who can quickly respond to the needs of required parts. Sometimes, the failure of a part in production can have serious consequences, even affecting other stations. Anıl Makina takes responsibility in eliminating such chain reactions and provides quick solutions to meet all your needs.

Machine Spare Part Manufacturing Machine spare part manufacturing is a specialized field that requires significant expertise. It requires high-quality equipment, experienced personnel, and production processes designed ergonomically according to the specifications of the spare part to be produced.

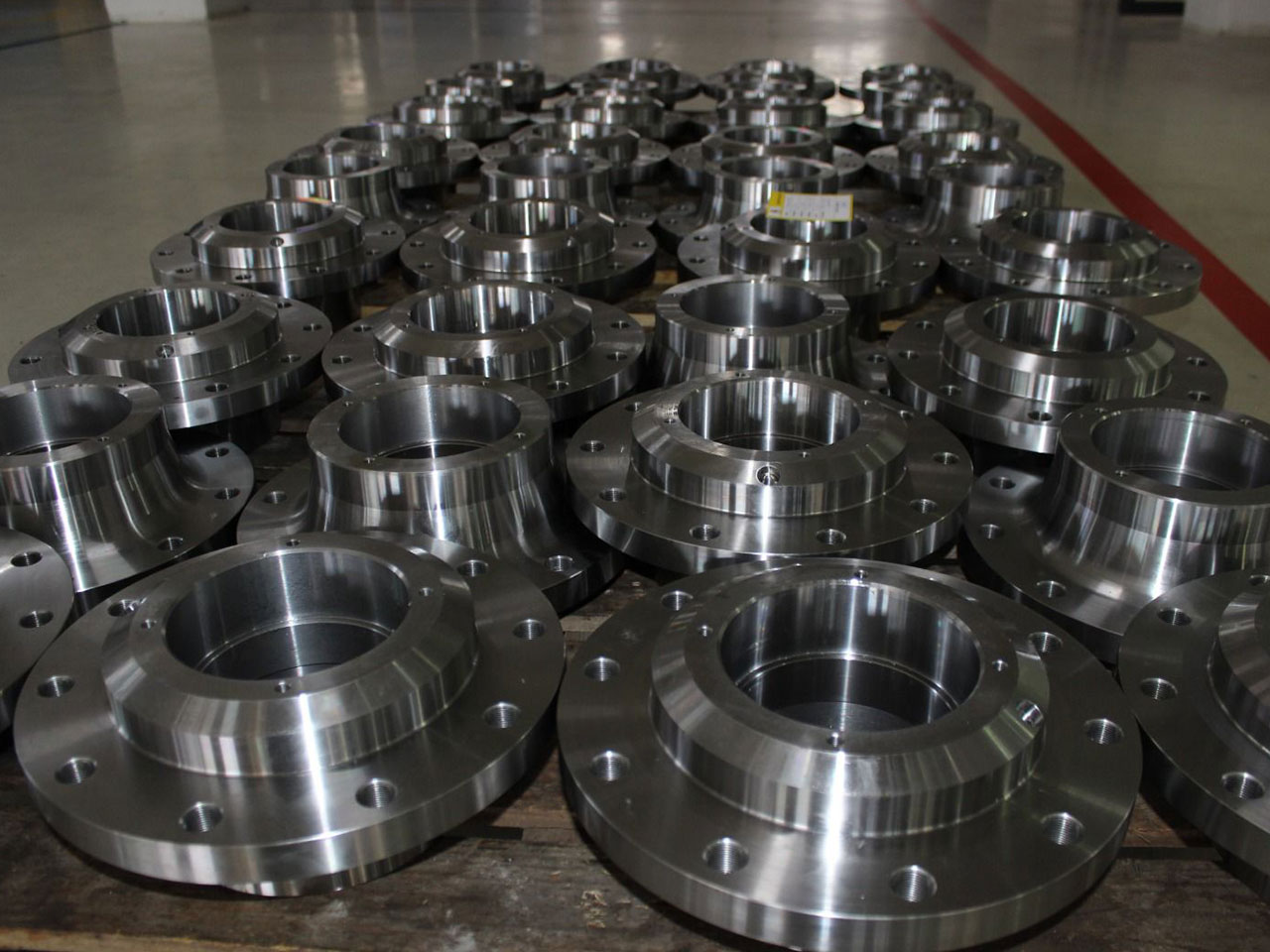

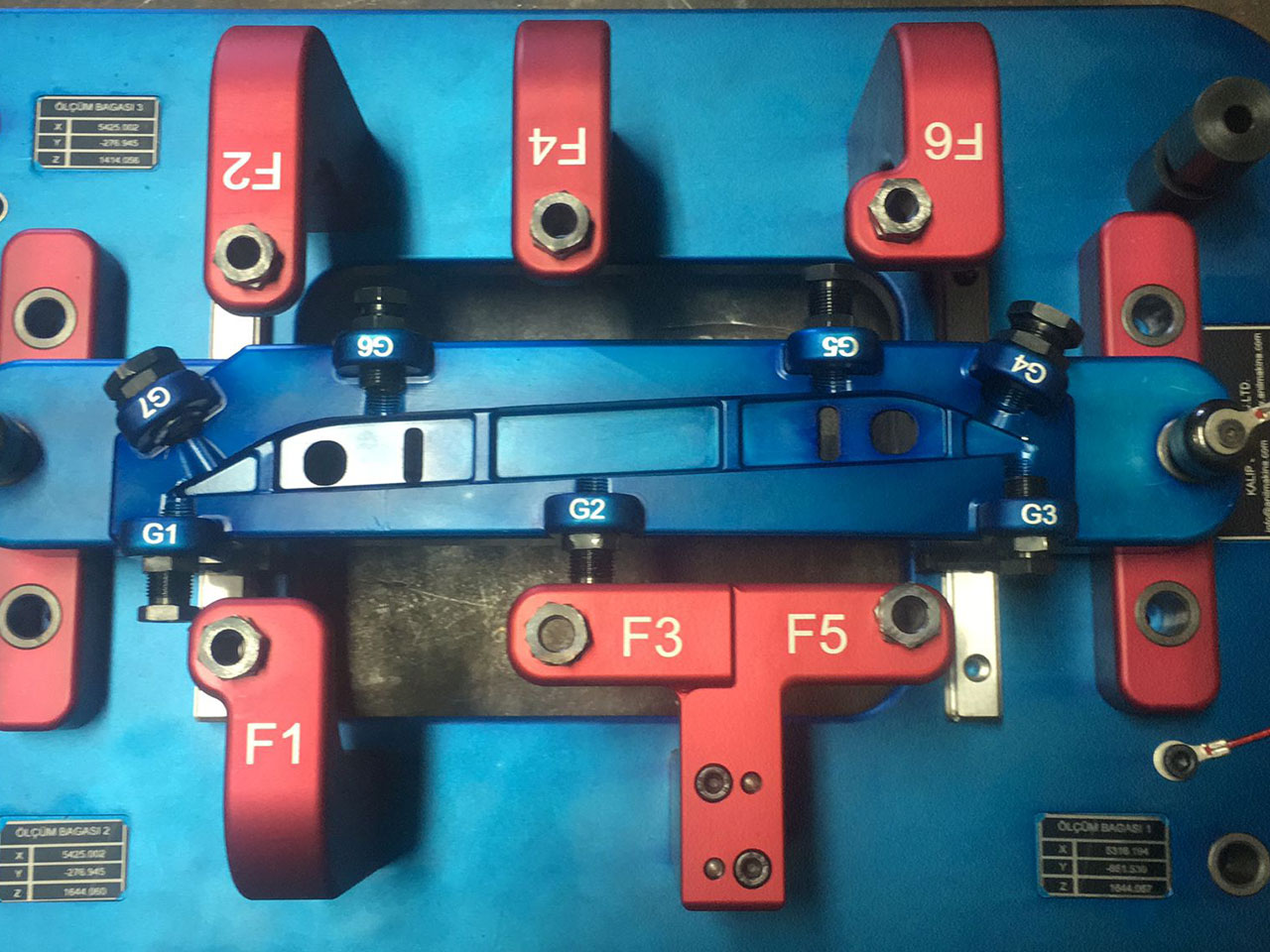

As Anıl Makina, with our experience in the industry and our team specialized in machine spare part manufacturing, we provide quick and reasonable solutions to meet the needs of today's industry. With our modern machine park and meticulous quality control processes, our spare part manufacturing activities are constantly monitored. From the beginning of the manufacturing process to the delivery stage, our quality control processes implemented at each station with meticulousness will leave no room for error, and the production process will be completed with customer satisfaction as our top priority according to our quality policy.

Quality is one of the most important factors directly affecting the outcome in machine spare part manufacturing. Although a spare part manufactured with the correct quality may be more expensive, it is safe, guaranteed, and made from high-quality materials.

Cheap and low-quality spare parts produced to cut costs have a shorter lifespan and can negatively affect other components when they fail to perform their function properly. It is also important not to overlook the possibility of encountering problems during assembly.

For these reasons, it is absolutely crucial to choose companies that have the necessary certifications, recognition, and references in machine spare part manufacturing.

We take pride in seeing that our shared vision with most of our customers is realized, and we subsequently receive large-scale re-ordering requests, thanks to our experience in serial part production, our state-of-the-art machine park, and our knowledgeable team. Starting from the product understanding, our engineers and operators closely monitor your design throughout the entire serial production process, ensuring that even your most complex designs can be flawlessly serially produced using our precise CNC machining techniques. Anıl Makina has a highly knowledgeable team ready to complete all your projects related to chip machining.

How Do We Work?

In our factory operating 24 hours a day, our trained programmers and operators reproduce all incoming prototypes in bulk quantities. All your projects can access a range of state-of-the-art machines such as our 5-axis CNC machine and CNC Lathe/Milling Centers equipped with robotic arms. Finished products are thoroughly tested for integrity, functionality, and quality using a reliable shipping system before being carefully packaged and dispatched.

The close relationship between our engineers, operators, and customers is the key to our success. By integrating all stakeholders into our serial production process, we reduce delivery times and costs. The ease of communication between our teams eliminates the possibility of errors.

While striving for efficiency, it is important to note that we give each project the attention it deserves.

What are the Benefits of CNC Machining for Serial Production? CNC machining is a highly efficient manufacturing process that provides numerous benefits for serial production. Some of the key advantages include:

-

Precision: CNC machines offer high precision and accuracy, ensuring consistent quality across all parts produced.

-

Speed: CNC machines can operate continuously and at high speeds, enabling faster production compared to traditional machining methods.

-

Cost-effectiveness: CNC machining reduces the need for manual labor and minimizes material waste, resulting in cost savings for serial production.

-

Versatility: CNC machines can handle a wide range of materials, including metals, plastics, and composites, allowing for versatile production capabilities.

-

Reproducibility: CNC machines can replicate complex designs and geometries with ease, ensuring consistent results in serial production.

-

Scalability: CNC machining is well-suited for both small-scale and large-scale production, making it adaptable to varying production volumes.

By leveraging these benefits, Anıl Makina aims to provide efficient and high-quality serial production services to meet the diverse needs of our customers.

If you have any further questions or if there's anything else I can assist you with, please let me know.